Click on each tab to open for more information. Click tab again to close.

Project management of a multi-million dollar investigation / remediation of an area impacted by decades of petroleum marketing in the area. Releases from the petroleum facilities in the area have led to the accumulation of free product beneath a residential community. Key aspects of this project included:

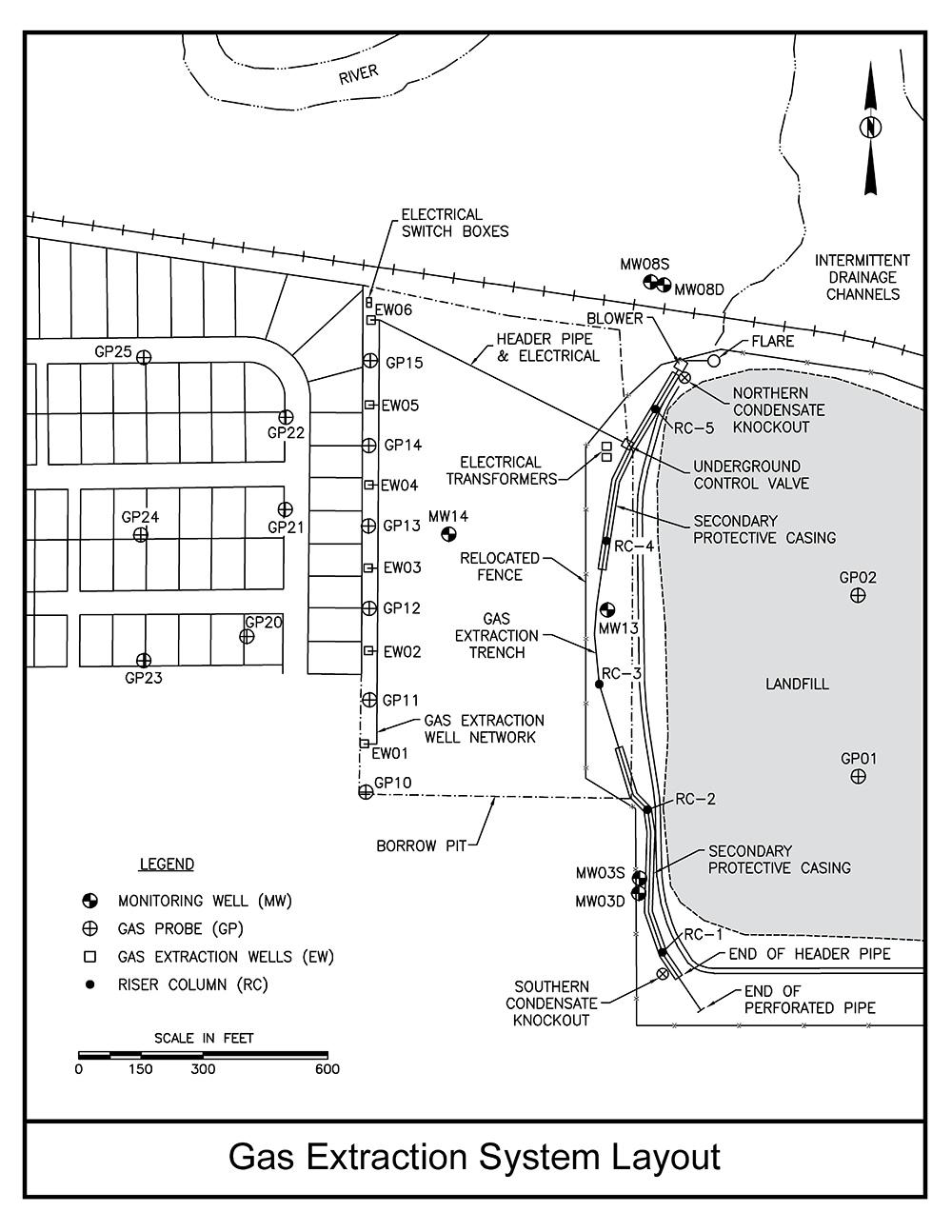

A former municipal landfill occupying 50 acres received household, municipal, commercial, and industrial refuse for 20 years. A project team managed by an SMA Principal evaluated and mitigated the intrusion of methane gas that had migrated into an adjacent residential subdivision. The Illinois Emergency Management Agency (IEMA) established a command center in the subdivision to direct emergency action activities.

A former municipal landfill occupying 50 acres received household, municipal, commercial, and industrial refuse for 20 years. A project team managed by an SMA Principal evaluated and mitigated the intrusion of methane gas that had migrated into an adjacent residential subdivision. The Illinois Emergency Management Agency (IEMA) established a command center in the subdivision to direct emergency action activities.

SMA activities on this project included:

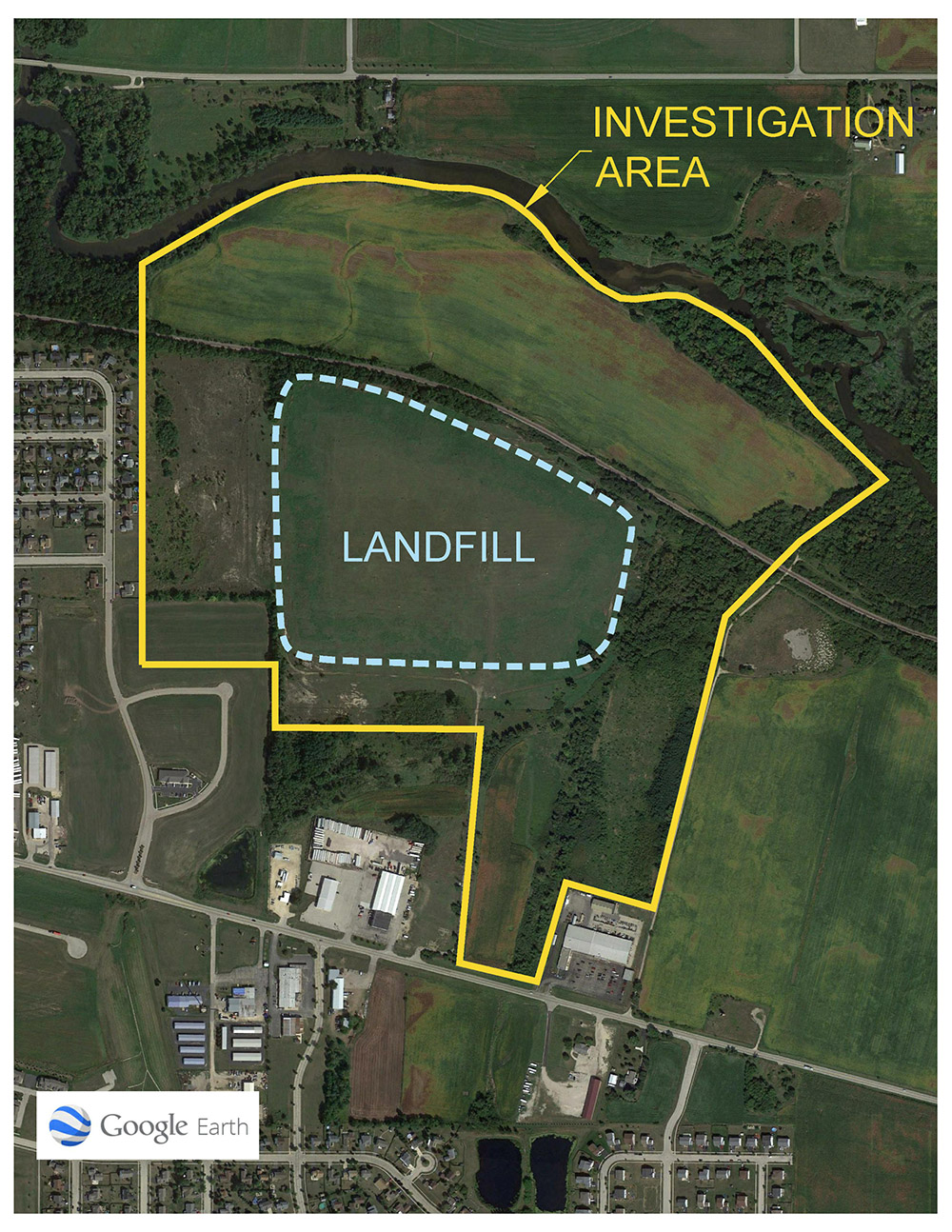

A former municipal landfill occupying 50 acres received household, municipal, commercial, and industrial refuse for 20 years. After the landfill was abandoned, the U.S. Environmental Protection Agency (EPA) evaluated the site and noted potential exposure pathways of direct contact with surface water and groundwater. The landfill was subsequently placed on the National Priorities List (NPL). A Project Team managed by an SMA Principal conducted a $2,000,000+ Remedial Investigation/Feasibility Study (RI/FS).

A former municipal landfill occupying 50 acres received household, municipal, commercial, and industrial refuse for 20 years. After the landfill was abandoned, the U.S. Environmental Protection Agency (EPA) evaluated the site and noted potential exposure pathways of direct contact with surface water and groundwater. The landfill was subsequently placed on the National Priorities List (NPL). A Project Team managed by an SMA Principal conducted a $2,000,000+ Remedial Investigation/Feasibility Study (RI/FS).

Activities at the Site included:

SMA is currently managing a multi-million dollar soil, groundwater, and LNAPL investigation and remediation project at a former petroleum refinery and distribution terminal in Illinois. Work is being performed pursuant to a Consent Order with the State of Illinois.

SMA activities on the Project include:

A 4.5-acre apartment development in Columbus, Indiana was historically utilized by a metals foundry and castings facility for unspecified waste storage between 1980 and 2003. The developer hired St. John – Mittelhauser & Associates, Inc. (SMA) to perform environmental investigations to delineate and characterize multiple chemical source areas; and then to contract and oversee the remediation of these areas through a combination of risk assessment, excavation and disposal of contaminant impacted soils, and the installation of vapor intrusion mitigation systems within 30,500 square feet of residential living space. The project is being completed in cooperation with the Indiana Department of Environmental Management’s Voluntary Remediation Program, and the Indiana Brownfields Program.

A 4.5-acre apartment development in Columbus, Indiana was historically utilized by a metals foundry and castings facility for unspecified waste storage between 1980 and 2003. The developer hired St. John – Mittelhauser & Associates, Inc. (SMA) to perform environmental investigations to delineate and characterize multiple chemical source areas; and then to contract and oversee the remediation of these areas through a combination of risk assessment, excavation and disposal of contaminant impacted soils, and the installation of vapor intrusion mitigation systems within 30,500 square feet of residential living space. The project is being completed in cooperation with the Indiana Department of Environmental Management’s Voluntary Remediation Program, and the Indiana Brownfields Program.

SMA activities on the project include:

SMA was retained to evaluate and address historical soil and groundwater contamination at a large retail shelving manufacturing facility in northern Indiana. The areas of concern consisted of several former lagoons and ponds, which had reportedly received plating, paint, and solvent wastes materials from the facility prior to 1975. The site had elevated concentrations of VOCs (TCE, 111-TCA, cis-1,2-DCE) in groundwater that are flowing to off-site areas and discharging to a local river. The chlorinated solvent impacts were documented to encompass nearly a square mile footprint beneath both the facility and neighboring off-Site properties. The Site has received a Convenant-Not-to-Sue and a Certificate of Closure from the State of Indiana.

SMA activities on the Project included:

SMA provided project management for a soil and groundwater remediation project at an aviation gasoline LUST Site. SMA performed a remedial investigation to define the extent of Light Non-Aqueous Phase Liquid (LNAPL) and impacted groundwater and soil; and designed a remedial system consisting of a dual phase extraction (DPE) system. Key aspects of the project included:

SMA provided project management for a soil and groundwater remediation project at an aviation gasoline LUST Site. SMA performed a remedial investigation to define the extent of Light Non-Aqueous Phase Liquid (LNAPL) and impacted groundwater and soil; and designed a remedial system consisting of a dual phase extraction (DPE) system. Key aspects of the project included:

PCE was discharged to a sanitary line by a drycleaners within the shopping center and was subsequently released through a break in the sewer line. PCE concentrations in soil were as high as 13,000 mg/kg. Remediation attempts by prior consultants were unsuccessful due to the contamination being in tight clays. SMA personnel managed and performed oversight of the installation of an Electrical Resistive Heating (ERH) system to successfully remediate the soils.

PCE was discharged to a sanitary line by a drycleaners within the shopping center and was subsequently released through a break in the sewer line. PCE concentrations in soil were as high as 13,000 mg/kg. Remediation attempts by prior consultants were unsuccessful due to the contamination being in tight clays. SMA personnel managed and performed oversight of the installation of an Electrical Resistive Heating (ERH) system to successfully remediate the soils.

SMA activities on the project included:

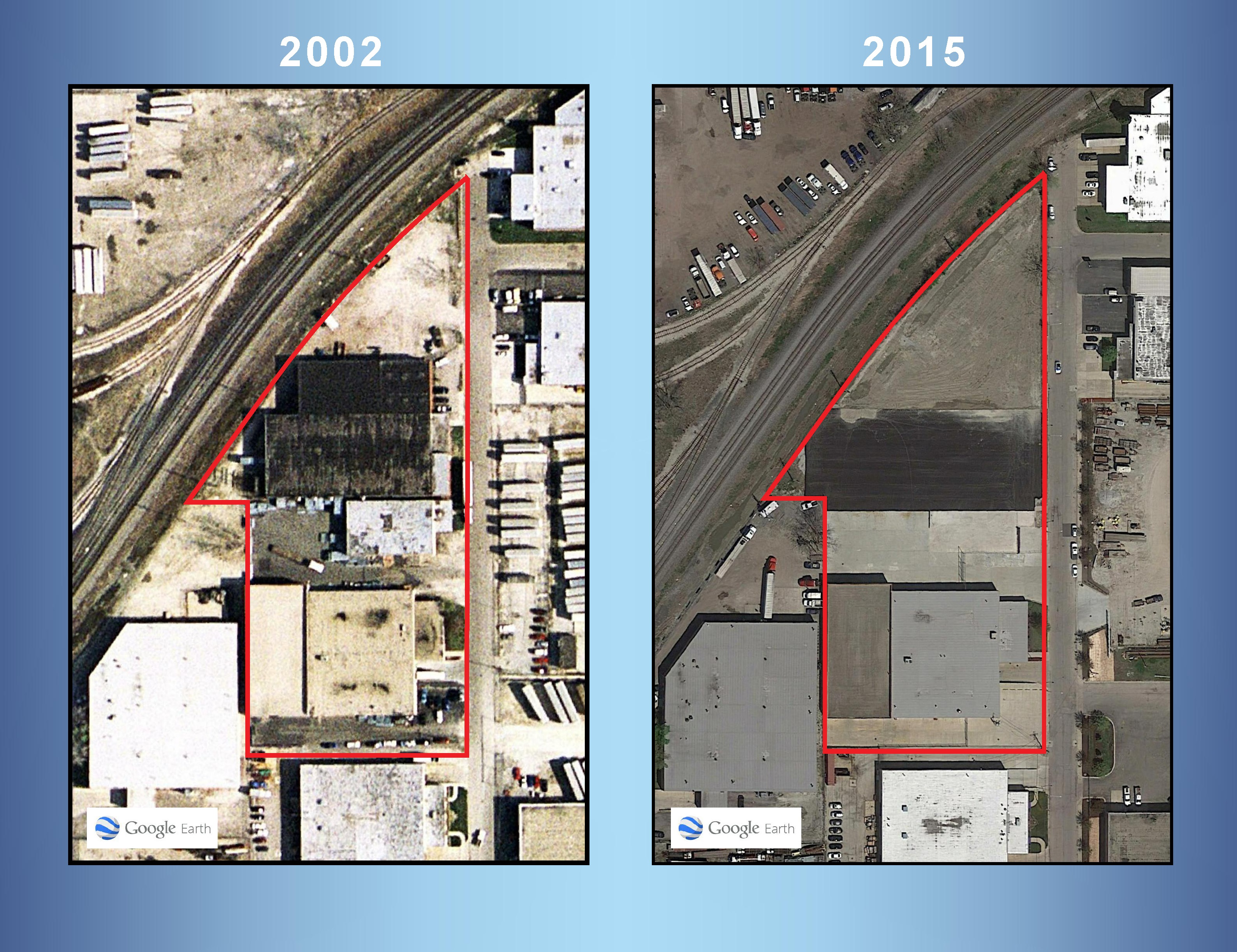

SMA performed investigations, decommissioning and demolition oversight, and remediation at a former electroplating facility in Chicago, Illinois. The facility performed hard chromium plating of locomotive crankshafts and grinding them to specification for the railroad industry for over 40 years.

SMA performed investigations, decommissioning and demolition oversight, and remediation at a former electroplating facility in Chicago, Illinois. The facility performed hard chromium plating of locomotive crankshafts and grinding them to specification for the railroad industry for over 40 years.

SMA activities on the project included:

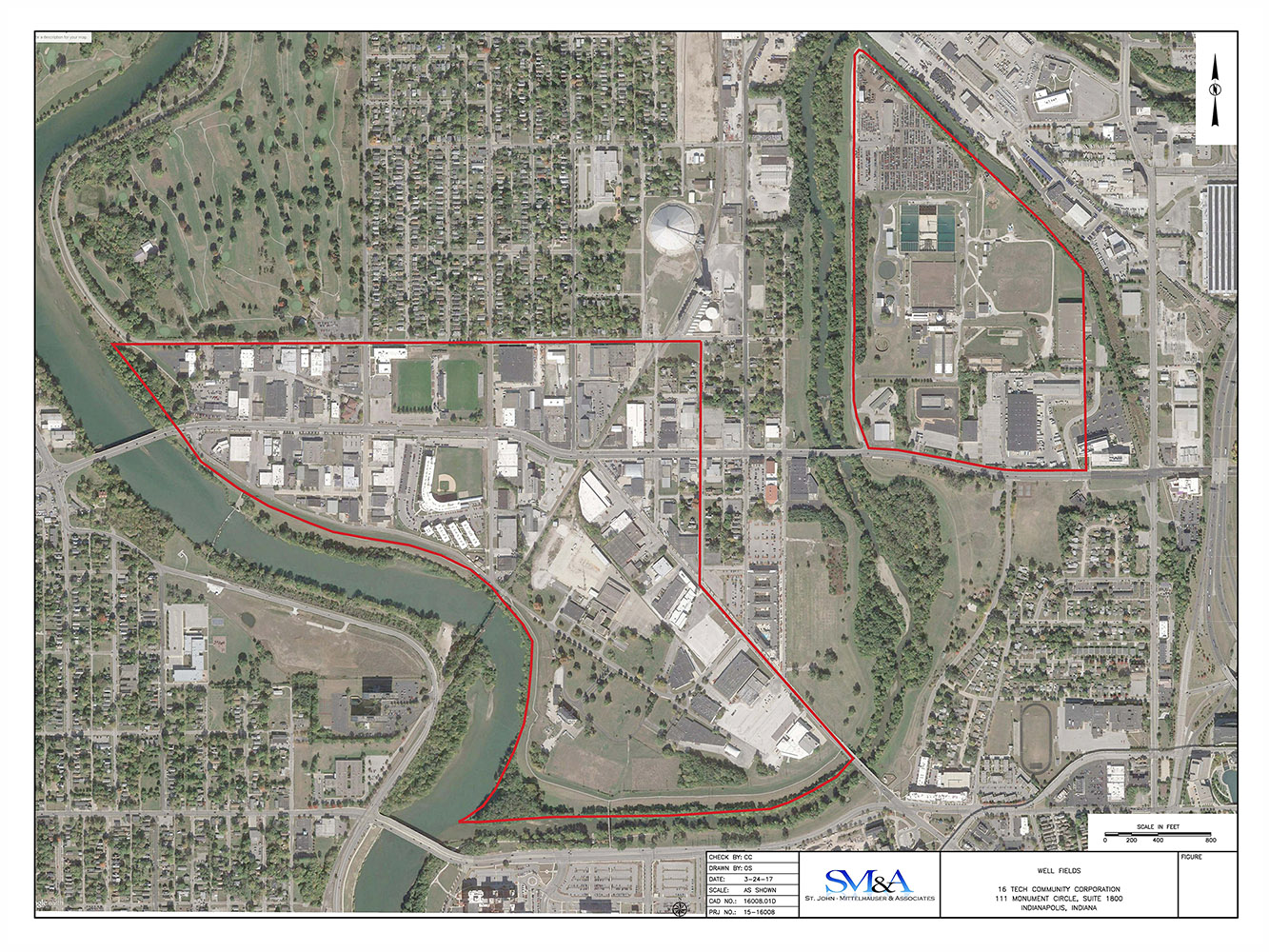

SMA represents a stakeholder in the development of the 16Tech corridor on the near northwest side of Indianapolis. The municipal water supply for the City of Indianapolis is provided by Citizen’s Energy Group (CEG), which operates an extensive well-field at the confluence of Fall Creek and the White River. The wells completed within the well field are completed in the alluvium associated with the river and creek, and in the carbonate bedrock.The 16Tech development is located within the CEG well field area.

SMA represents a stakeholder in the development of the 16Tech corridor on the near northwest side of Indianapolis. The municipal water supply for the City of Indianapolis is provided by Citizen’s Energy Group (CEG), which operates an extensive well-field at the confluence of Fall Creek and the White River. The wells completed within the well field are completed in the alluvium associated with the river and creek, and in the carbonate bedrock.The 16Tech development is located within the CEG well field area.

Portions of the well-field have experienced impacts by chlorinated volatile organic compounds (CVOCs) since at least the 1980’s. The source of these impacts is likely from current andformer sources that may be as far as miles from the well-field. Cumulatively, the 19 CEG production wells pump approximately 14.5 million gallons of groundwater per day to be processed for drinking water. Historically, the CVOC plume has had little to no impact to the finished water of the system, but the well-field received a Hazardous Ranking System (HRS) score greater than 28.5. As a result, both the USEPA and the Indiana Department of Environmental Management (IDEM) proposed listing the site on the National Priorities List.

SMA Activities at the Site included:

As a result of this work, the IDEM has decided to withdraw their support for the listing of the site on the NPL. The decision regarding the potential NPL listing from the USEPA is still pending.

SMA conducted site investigations and groundwater sampling under the Voluntary Remediation Program (VRP) for a site in Brookville, Indiana that is impacted with trichloroethene (TCE). The site is in close proximity to private wells and the Whitewater River. The source area on-site has impacted the Whitewater River alluvium with TCE.

SMA conducted site investigations and groundwater sampling under the Voluntary Remediation Program (VRP) for a site in Brookville, Indiana that is impacted with trichloroethene (TCE). The site is in close proximity to private wells and the Whitewater River. The source area on-site has impacted the Whitewater River alluvium with TCE.

SMA has performed the following activities at the site:

The Anderson Redevelopment Commission (ARC) has hired SMA to complete the investigations to delineate/characterize the TCE source area and oversee the electrical resistance heating (ERH) remediation of the source area at the former General Motors (GM) Plant 7 site. This work is being performed to complete the obligations for the RCRA Corrective Action at the former GM site in Anderson, and is governed by a consent order with U.S. EPA Region 5 that requires the soil and groundwater remediation. ERH was selected as the remedial technology because of its ability to remediate fine-grained soils and saturated zone soils (below the water table) to low cleanup levels for chlorinated solvents, even when DNAPL is present. The negotiated clean-up objective for TCE in the soil is 15 mg/kg.

The Anderson Redevelopment Commission (ARC) has hired SMA to complete the investigations to delineate/characterize the TCE source area and oversee the electrical resistance heating (ERH) remediation of the source area at the former General Motors (GM) Plant 7 site. This work is being performed to complete the obligations for the RCRA Corrective Action at the former GM site in Anderson, and is governed by a consent order with U.S. EPA Region 5 that requires the soil and groundwater remediation. ERH was selected as the remedial technology because of its ability to remediate fine-grained soils and saturated zone soils (below the water table) to low cleanup levels for chlorinated solvents, even when DNAPL is present. The negotiated clean-up objective for TCE in the soil is 15 mg/kg.

Specific activities which SMA has completed on the project include:

Future SMA activities on the project include:

The Madison, Indiana site is a former bulk storage terminal that had a series of 20,000 to 50,000 gallon above ground tanks that primarily stored a variety of petroleum products and distillates. One tank was also used to store chlorinated solvents. On-loading and off-loading handling practices to these tanks resulted in releases of petroleum hydrocarbons, petroleum distillates, and chlorinated solvents at the site. The site is located along the Ohio River and is situated between two municipal water well fields that serve the City of Madison and a State Hospital. SMA reviewed previous reports generated by the prior consultants and devised a scope of work that would be used to define the limits of the source areas and developed a site conceptual model to obtain a better understanding of site subsurface transport processes.

The Madison, Indiana site is a former bulk storage terminal that had a series of 20,000 to 50,000 gallon above ground tanks that primarily stored a variety of petroleum products and distillates. One tank was also used to store chlorinated solvents. On-loading and off-loading handling practices to these tanks resulted in releases of petroleum hydrocarbons, petroleum distillates, and chlorinated solvents at the site. The site is located along the Ohio River and is situated between two municipal water well fields that serve the City of Madison and a State Hospital. SMA reviewed previous reports generated by the prior consultants and devised a scope of work that would be used to define the limits of the source areas and developed a site conceptual model to obtain a better understanding of site subsurface transport processes.

SMA activities at the Site include:

SMA personnel were hired by Environmental Business Solutions, Inc. (EBS) and West Environmental, Inc. (West) to help them remediate the former Norman’s Cleaner site in Eureka, California through use of electrical resistance heating (ERH). SMA’s role on the project has been to obtain the most cost effective and functional ERH design for the remediation of tetrachloroethylene (PCE) at the site. SMA was selected for design oversight due to the success of the previous 11 ERH projects that we have completed. SMA has worked closely with EBS/West and the ERH contractor to implement the ERH design.

SMA personnel were hired by Environmental Business Solutions, Inc. (EBS) and West Environmental, Inc. (West) to help them remediate the former Norman’s Cleaner site in Eureka, California through use of electrical resistance heating (ERH). SMA’s role on the project has been to obtain the most cost effective and functional ERH design for the remediation of tetrachloroethylene (PCE) at the site. SMA was selected for design oversight due to the success of the previous 11 ERH projects that we have completed. SMA has worked closely with EBS/West and the ERH contractor to implement the ERH design.

The PCE releases at the facility have impacted subsurface soil and groundwater at the site and the groundwater has migrated beneath the street adjacent to the facility. The ERH system will remediate site soils and groundwater to the cleanup objectives. The ERH system is installed both on site and in the adjacent street to perform heating there. The ERH system has operation of the ERH system is on-going and the remediation is nearing completion.

SMA activities on the project include:

A Project Team managed by current SMA employees was retained by a confidential client to provide environmental services at their Hammond, Indiana facility. The Project Team was contacted in response to correspondence the client received from the Indiana Department of Environmental Management (IDEM) concerning an inspection of stored materials at their facility.

A Project Team managed by current SMA employees was retained by a confidential client to provide environmental services at their Hammond, Indiana facility. The Project Team was contacted in response to correspondence the client received from the Indiana Department of Environmental Management (IDEM) concerning an inspection of stored materials at their facility.

The client operates a small pest control company that had stored pesticide products in storage buildings on an adjacent property since the 1970s. During storage, the pesticide containers began to deteriorate, releasing material into the environment. Several pesticide containers and released materials were observed in the storage buildings during an IDEM inspection. Under an agreed order, IDEM declared the footprint of the storage buildings a Hazardous Waste Management Unit (HWMU) and requested that the unit be closed appropriately.

The SMA Project Team’s activities have included:

SMA provides hydrogeologic oversight of soil and groundwater investigation and remediation activities for the former Indiana Steel & Wire (IS&W) facility site in Muncie, Indiana. The steel manufacturing of wire began at the IS&W facility in 1902 and continued in constant operation through 2004. In addition to steel wire fabrication the facility performed a variety of different types of metal plating operations. The plating operations included: electroforming, galvanizing and copper-cyanide plating. The facility also performed sodium cyanide heat treating. Widespread soil contamination had resulted from operations within multiple process units and sewer leaks, disposal into a pit, disposal into a former rock quarry, and disposal at three landfills on site. Extensive groundwater contamination of zinc, ammonia, chlorides, sulfates, cyanide, copper, fluoride, lead and nickel resulted from the releases at the operational units.

SMA provides hydrogeologic oversight of soil and groundwater investigation and remediation activities for the former Indiana Steel & Wire (IS&W) facility site in Muncie, Indiana. The steel manufacturing of wire began at the IS&W facility in 1902 and continued in constant operation through 2004. In addition to steel wire fabrication the facility performed a variety of different types of metal plating operations. The plating operations included: electroforming, galvanizing and copper-cyanide plating. The facility also performed sodium cyanide heat treating. Widespread soil contamination had resulted from operations within multiple process units and sewer leaks, disposal into a pit, disposal into a former rock quarry, and disposal at three landfills on site. Extensive groundwater contamination of zinc, ammonia, chlorides, sulfates, cyanide, copper, fluoride, lead and nickel resulted from the releases at the operational units.

SMA work at the site has included:

In 2004, KS Gleitlager USA (f/k/a KS Bearings), hired SMA to take over the role as project manager and lead investigator for their site in Greensburg, Indiana. The site is enrolled in the Indiana Voluntary Remediation Program (VRP). The previous consultant working on the site had struggled to determine source areas of TCE contamination at the site, and was in the process of implementing remedial measures. Subsequent investigative work performed by SMA identified approximately seven separate source areas of PCE and TCE impacts to soil and groundwater. SMA also identified a large area of surficial lead impacted soil, and surficial hexavalent chromium impacts to a drainage area. The groundwater impacts by PCE and TCE were delineated across the site, and adjacent properties.All work at the site was performed pursuant to an Agreed Order with the Indiana Department of Environmental Management (IDEM).

In 2004, KS Gleitlager USA (f/k/a KS Bearings), hired SMA to take over the role as project manager and lead investigator for their site in Greensburg, Indiana. The site is enrolled in the Indiana Voluntary Remediation Program (VRP). The previous consultant working on the site had struggled to determine source areas of TCE contamination at the site, and was in the process of implementing remedial measures. Subsequent investigative work performed by SMA identified approximately seven separate source areas of PCE and TCE impacts to soil and groundwater. SMA also identified a large area of surficial lead impacted soil, and surficial hexavalent chromium impacts to a drainage area. The groundwater impacts by PCE and TCE were delineated across the site, and adjacent properties.All work at the site was performed pursuant to an Agreed Order with the Indiana Department of Environmental Management (IDEM).

Other SMA activities at the site included:

In December 2000, the Illinois EPA identified approximately 3,000 private residences that were potentially affected by a 3-mile long groundwater plume of chlorinated solvents from the Lockformer facility in Lisle, IL. In 2001, Ron St. John, SMA, was identified as the Project Coordinator for both the U.S. EPA 106 Order, and the Illinois EPA Consent Order that governed the investigation and remediation work at Lockformer. Investigation activities included defining the extent of soil and groundwater contamination related to releases on the Lockformer site; and identifying other sources of chlorinated solvent contamination in the Silurian Dolomite aquifer in the general area.

In December 2000, the Illinois EPA identified approximately 3,000 private residences that were potentially affected by a 3-mile long groundwater plume of chlorinated solvents from the Lockformer facility in Lisle, IL. In 2001, Ron St. John, SMA, was identified as the Project Coordinator for both the U.S. EPA 106 Order, and the Illinois EPA Consent Order that governed the investigation and remediation work at Lockformer. Investigation activities included defining the extent of soil and groundwater contamination related to releases on the Lockformer site; and identifying other sources of chlorinated solvent contamination in the Silurian Dolomite aquifer in the general area.

SMA activities at the Site included:

SMA was retained by Monarch Textile Rental Services, Inc. (Monarch) to take over the extent of contamination investigations and remedial activities for their site in South Bend, Indiana. Based on the initial site investigations by SMA, two source areas of tetrachloroethene (PCE) contamination were identified.

SMA was retained by Monarch Textile Rental Services, Inc. (Monarch) to take over the extent of contamination investigations and remedial activities for their site in South Bend, Indiana. Based on the initial site investigations by SMA, two source areas of tetrachloroethene (PCE) contamination were identified.

SMA activities at the Site include:

The 61 acre Northside Sanitary Landfill began accepting waste in the 1960s and operated until 1991. It accepted municipal solid waste, Resource Conservation and Recovery Act (RCRA) hazardous waste, and other forms of commercial and industrial waste. The site is being remediated pursuant to a federal court Consent Decree entered in 1991, which mandates the remediation of 29 individual constituents of concern including volatile organic compounds, semi-volatile organic compounds and priority pollutant metals. SMA was hired to perform project coordinator activities and oversee all investigation and remediation activities at the site.

The 61 acre Northside Sanitary Landfill began accepting waste in the 1960s and operated until 1991. It accepted municipal solid waste, Resource Conservation and Recovery Act (RCRA) hazardous waste, and other forms of commercial and industrial waste. The site is being remediated pursuant to a federal court Consent Decree entered in 1991, which mandates the remediation of 29 individual constituents of concern including volatile organic compounds, semi-volatile organic compounds and priority pollutant metals. SMA was hired to perform project coordinator activities and oversee all investigation and remediation activities at the site.

SMA activities on the Project include:

SMA was retained by The City of Scottsburg, Indiana to perform extent of contamination investigations and remedial activities at a Brownfields site formerly occupied by Scott Manufacturing. Based on the initial site investigations, several source areas of 1,1,1-trichloroethane (1,1,1-TCA) contamination was identified.

SMA was retained by The City of Scottsburg, Indiana to perform extent of contamination investigations and remedial activities at a Brownfields site formerly occupied by Scott Manufacturing. Based on the initial site investigations, several source areas of 1,1,1-trichloroethane (1,1,1-TCA) contamination was identified.

SMA activities at the Site included:

The former manufactured gas plant (MGP) occupied approximately 4.2 acres in the southeast corner of the 12.8-acre property that is located along a major river. The operations of the former MGP facility has left the Site subsurface with contamination comprised of a wide range of chemicals formed during the incomplete combustion of coal, oil and gas. These compounds range from VOCs such as benzene, toluene, ethylbenzene and xylenes (BTEX) to polyaromatic hydrocarbons (PAHs). Subsurface impact includes pervasive soil contamination, impacted groundwater, as well as pools of concentrated NAPLs.

The former manufactured gas plant (MGP) occupied approximately 4.2 acres in the southeast corner of the 12.8-acre property that is located along a major river. The operations of the former MGP facility has left the Site subsurface with contamination comprised of a wide range of chemicals formed during the incomplete combustion of coal, oil and gas. These compounds range from VOCs such as benzene, toluene, ethylbenzene and xylenes (BTEX) to polyaromatic hydrocarbons (PAHs). Subsurface impact includes pervasive soil contamination, impacted groundwater, as well as pools of concentrated NAPLs.

A series of past remediation efforts have occurred at the Site such as the removal of buried former MGP equipment, excavation of soils and the installation of a 2.3-acre clay engineered barrier. An interceptor trench was also constructed along the downgradient Site boundarywhere contaminated groundwater entering this trench is collected and pumped to an onsite treatment building.

SMA was retained to aide in the design, installation, operation, and maintenance of an ERH and MPE system that was used as a remediational feasibility pilot study for the site.

SMA activities on the pilot study consisted of:

The Carlin Combustion Technology, Inc. (Carlin) has manufactured a variety of furnace and boiler components from the late 1940’s to present at the East Longmeadow facility. From the late 1940’s to 1992, chlorinated solvents were used in degreasing operations in the facility to prepare parts for finishing. As part of due diligence for a property transfer in 2009, soil and groundwater sampling identified tetrachloroethene (PCE) and trichloroethene (TCE) impacts at the site. SMA was hired to perform project coordinator activities and oversee all investigations and remediation at the site. Activities at the site performed to date include: