Click on each tab to open for more information. Click tab again to close.

ERH is a technology that uses electrical current to heat subsurface soils and groundwater. The input electricity is conducted thru water in the unsaturated soils, or through groundwater, and the soils act as resistors, thereby causing the soils to be heated.

The figure below shows a typical electrode array (the cylindrical objects with a white top). Subsurface vapors (see horizontal piping) are collected under vacuum and fed to a vapor treatment system (not shown) where the water is separated and the off-gas containing volatile organics are either treated or discharged to the atmosphere, depending on regulatory requirements.

The technology is ideally suited for removal of volatile organics like TCE, PCE, VC and BETX in impermeable soils, and treatment of DNAPL. The technology can be used inside buildings, and the remediation is typically complete in less than a year.

SMA staff has remediated eleven sites using this technology, some under a firm fixed- price guarantee. For more details on this technology see ERH FAQ's.

Video captured from a drone showing an ERH system installed by SMA

Time-lapse animation of an ERH remediation system in action

Multi-Phase Extraction (MPE) is a generic term for technologies that extract groundwater, LNAPL, and hydrocarbon vapor from the subsurface, remediating dissolved, vapor, residual, and non-aqueous phases of contamination. SMA employees have designed, installed, operated, and maintained hundreds of MPE systems at sites all across the country.

Depending of your specific site conditions such as the presence of LNAPL in both the saturated and vadose zones, low to moderate soil permeability, infeasible or cost prohibitive ex-situ soil treatment options, and remediation time and endpoint constraints, SMA can design an effective MPE system for your site. In particular, low permeability formations tend to possess thick capillary zones with LNAPL held in the pore spaces by capillary forces at less than atmospheric pressure. The vacuum enhancement by MPE can overcome these capillary forces and remove the LNAPL from the subsurface.

SMA can design an MPE system tailored to your specific site conditions that incorporates your business’ environmental compliance, schedule, and budget within a single design. We have installed MPE systems at sites ranging in size from small retail gas stations to large petroleum refineries and international airports. SMA has also designed, installed, and operated mobile systems for HVR and DPE that are capable “self-sufficient” operation utilizing an internal combustion engine (ICE) that uses the engine manifold to create vacuum, and the recovered hydrocarbon vapor (with propane make-up) as fuel. The ICE also supplies its own power that can be used for the system controls, compressed air generation, water/LNAPL transfer and treatment, and alarm monitoring and callouts. (Reference Project).

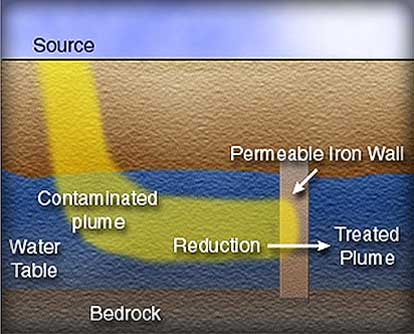

A permeable reactive barrier (PRB) is a permeable wall that is installed in the subsurface that allows groundwater to flow through it, and during the process of flowing through it, the groundwater is treated and rendered non-toxic. PRBs are constructed of a variety of materials that are selected on the basis of the contaminant in groundwater that needs to be treated. Typically, a trench is excavated perpendicular the flow path of the groundwater contamination plume, and is filled with treatment agents (zero-valent iron, chelators, sorbents, compost, and bioreactors). The most common reagent is zero-valent iron (iron fillings) to treat chlorinated solvents. The barrier walls allow the passage of groundwater through them while treating or sorbing the contaminant during the groundwater migration through the barrier. The groundwater velocity at the site, magnitude of contamination, and type of contaminant dictates the materials used and the thickness of the PRB.

Sophisticated construction equipment and techniques have been employed to facilitate the installation of PRBs to depths greater than those allowed by standard excavation techniques. The deepest full-scale PRB installed to date is 105 feet below grade.

Used by permission of MERL

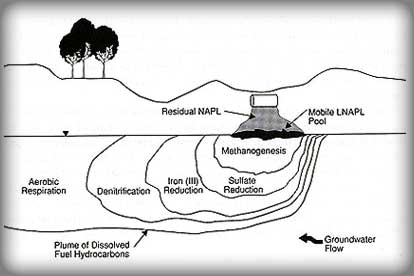

Chlorinated solvents and petroleum hydrocarbons in groundwater can be remediated in-situ by biological means in a large number of instances. When remediating petroleum hydrocarbons in groundwater, microorganisms break down individual contaminants by using them as a food source. When remediating chlorinated solvents in groundwater, microorganisms usually utilize other organic carbon within the aquifer as a food source and utilize the chlorinated solvents as an electron acceptor to respirate, and as a consequence reductively dechlorinate the chlorinated compounds.

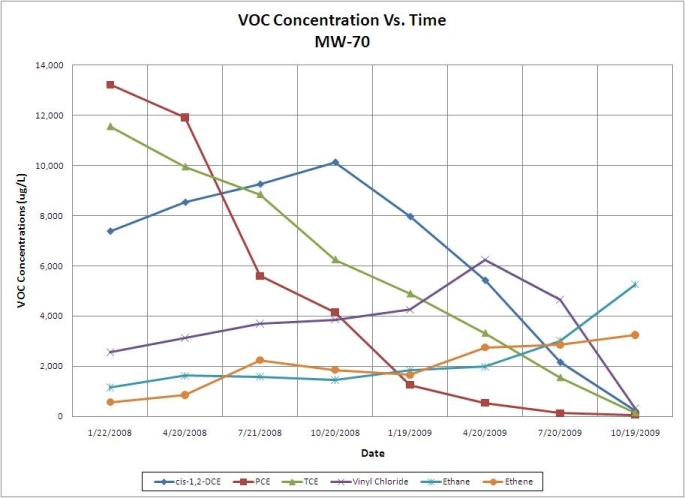

SMA scientists and hydrogeologists have performed large (over approximately 20-acres of aquifer), full-scale bioremediation of chlorinated solvents in groundwater to remediate trichloroethene (TCE) to the non-toxic end product ethene and other mineralized constituents. SMA has done this at sites where only the indigenous micro-biologic community was utilized to perform the remedial measure and at sites where it was necessary to introduce an inoculum known to contain dehalococoides (the only group of microorganisms known to completely degrade TCE to ethene).

Adapted from Lovely, D.R.; Chapelle, F.H., and Woodward, J.C. 1994. Environmental Science and Technology, Vol.28, No.7, pp. 1205-1210.

Chlorinated solvent concentrations in a monitoring well exhibiting complete reductive dechlorination to the non-toxic end products ethene and ethane after implementation of groundwater bioremediation efforts

Time-lapse animation showing the remediation of perchloroethylene (PCE) and other chlorinated solvents in groundwater at a dry cleaner

Vapor intrusion occurs when vapor-forming chemicals migrate from a subsurface source into an interior of a structure. Utilizing specialized vacuum canisters air can be analyzed to determine concentrations of chemicals present in the soil directly beneath a structure, directly beneath the concrete slab of a structure, or any part of the breathable air zone in a structure. This data is used to determine the need for soil or groundwater remediation that is source for the migrating vapors, and/or the installation of an active or passive vapor remediational system for the structure.

SMA conducts demolition management and oversight to ensure the proper environmental and governmental procedures are being completed. SMA ensures the proper permits for utility disconnects, proper asbestos abatement, and lead survey/abatement are complete. When the demolition is underway, dust and other environmental monitoring is conducted to ensure the safety of the workers and the surrounding area. If needed, testing and special disposal of some or all of the demolished material is managed as well.

Soil stabilization/fixation is the process of adding a chemical to the soil in order to immobilize contaminates, generally rendering the soil as non-hazardous. Once the contamination is locked within the soil it can be disposed of in a different manner then if it wasn’t stabilized, or in some cases, left in place and capped with a barrier, greatly reducing disposal costs.

Soil excavation and trenching is used to remove contaminated soil from the site and dispose of it in an approved manner. Utilizing soil sampling data and SMAs 2D and 3D visualization, boundaries of soil needed to be excavated can be refined to limit the removal of un-impacted soils saving disposal costs. SMA verifies through surveys and/or soil sampling that the proper soils are removed. Characterization and suitable action when dealing with water infiltration into the excavation and backfilling/compaction of the excavation is also used.

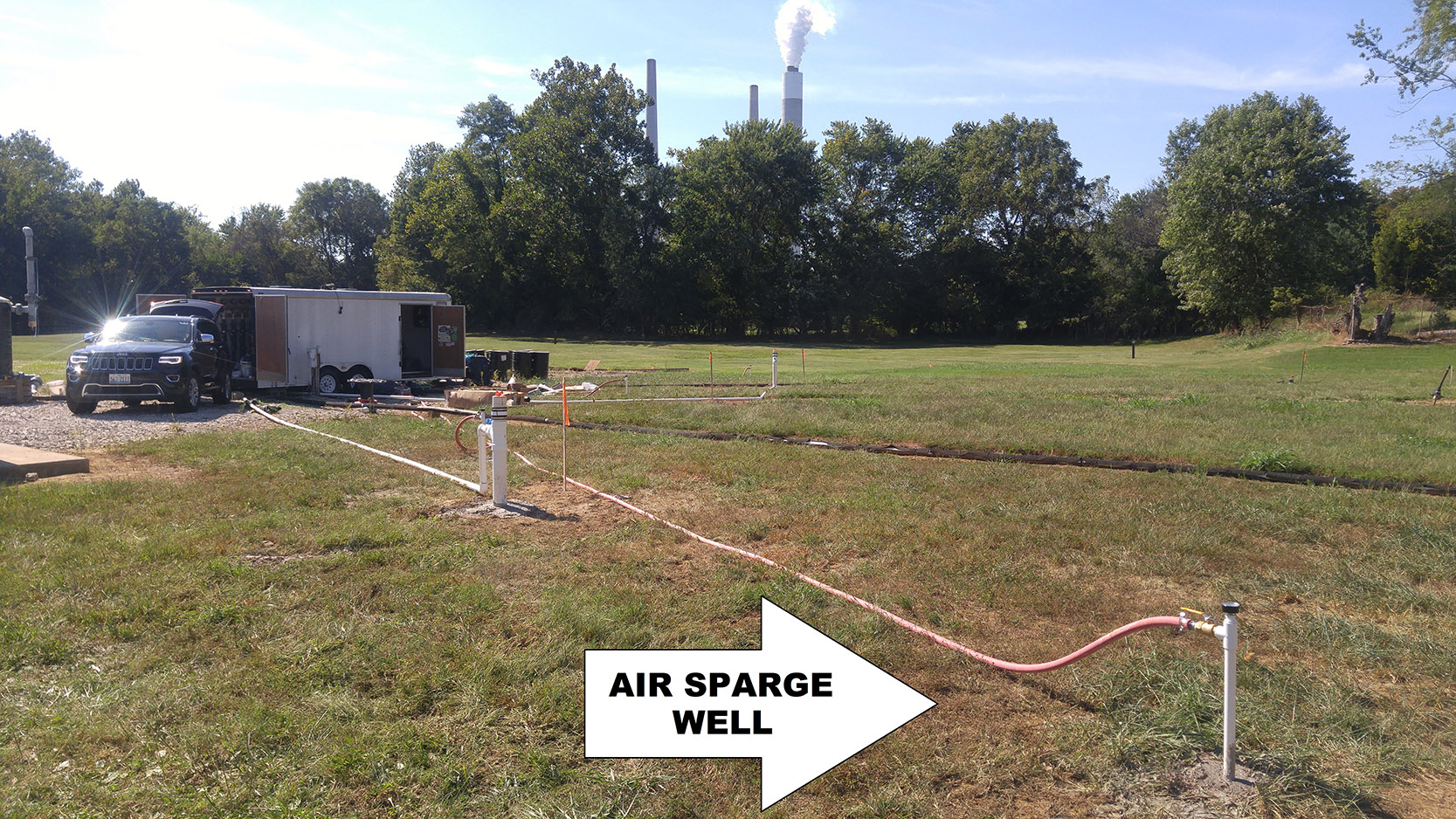

Air sparging is a groundwater remediation technology that forces air into the saturated zone in order to remove low-molecular weight or volatile contaminants via the vapor-phase. This technology is typically used in conjunction with SVE to facilitate the removal of the generated vapors form the subsurface. In addition, air sparging is also useful for increasing the amount of dissolved oxygen in groundwater and promoting aerobic biodegradation of the contaminants.

In situ chemical oxidation is a remediation technology that uses specific chemical compounds in order to destroy or oxidize a variety of contaminants. In situ chemical oxidation (ISCO) can remediate soil contamination in very short timeframes (days to weeks). However, the chemical oxidant needs to have direct contact with the contaminant in order for the ISCO technology to effectively remediate the soils. This requires that the soil contamination be relatively shallow (in the upper 20 feet), have the ability to be vigorously mixed with the chemical oxidant (the site needs to be accessible with an excavator), and have the ability to develop into a slurry with the chemical oxidant. Typically, this technology is very effective at sites with subsurface soils composed of sands or silts.

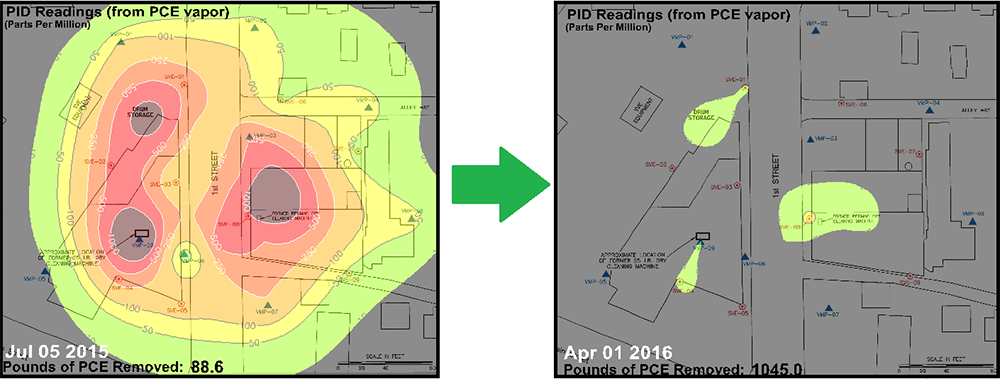

Soil vapor extraction (SVE) is a remediation technology that uses vacuum to remove low-molecular weight or volatile contaminants in the vapor-phase from subsurface soils at a low cost, and with minimal disruption to business operations. This technology is a viable remediation option in fine- to coarse-grained (sand and gravel) sediments. SMA has designed, pilot-tested, installed, operated, and maintained SVE systems across the Midwest. The image below shows how an SVE system effectively removed perchloroethylene (PCE) vapors from subsurface soils at an active dry cleaner in less than one year.

• Voluntary Cleanup Programs

• Cost Analysis and Feasibility Studies

• System Engineering and Process Design

• System Installation and Monitoring

• Thermal Heating

• Groundwater Gradient Control

• Interception Trenches