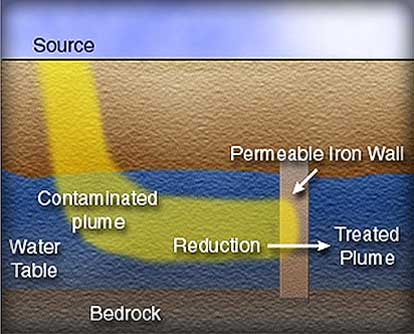

A permeable reactive barrier (PRB) is a permeable wall that is installed in the subsurface that allows groundwater to flow through it, and during the process of flowing through it, the groundwater is treated and rendered non-toxic. PRBs are constructed of a variety of materials that are selected on the basis of the contaminant in groundwater that needs to be treated. Typically, a trench is excavated perpendicular the flow path of the groundwater contamination plume, and is filled with treatment agents (zero-valent iron, chelators, sorbents, compost, and bioreactors). The most common reagent is zero-valent iron (iron fillings) to treat chlorinated solvents. The barrier walls allow the passage of groundwater through them while treating or sorbing the contaminant during the groundwater migration through the barrier. The groundwater velocity at the site, magnitude of contamination, and type of contaminant dictates the materials used and the thickness of the PRB.

Sophisticated construction equipment and techniques have been employed to facilitate the installation of PRBs to depths greater than those allowed by standard excavation techniques. The deepest full-scale PRB installed to date is 105 feet below grade.

Used by permission of MERL